Skid-mounted Fully Automated Direct Filtration System

Red Dog Mine, AK (Tech Resources)

The Red Dog Mine is located in central Alaska is a privately owned mining facility (Tech Resources) which has been in operation for several decades. The mine, which produces zinc, has several hundred employees, and also serves numerous contractors, sub-contractors and suppliers. Having an adequate supply of potable water is a must for this facility to function without interruption. The facility is served via barge and air transport only, with no roads connecting the facility to other parts of the state.

The old water filtration system was built when the mine originally opened and was lacking in capacity and performance. In early 2018, Tech Resources contracted with Heritage Contracting in Delta Junction, Alaska, to supply a water filtration system in a custom-built modular building and transport it to site via barge. This new system would operate as a stand-alone unit to supplement the old filtration system.

Heritage Contracting attempted to negotiate with several suppliers of water filtration units in the USA, however they were offered off-the shelf, systems which were not suitable to fit into the modular plan and did not meet the requirement of the engineering team at the site. The consulting engineering firm referred Heritage Contracting to UFG, based on previous experience which they had with UFG. UFG negotiated with Heritage Contracting and was awarded a contract to supply a custom-built, skid mounted water filtration system which would allow them to meet the requirement of the project.

Upgrades

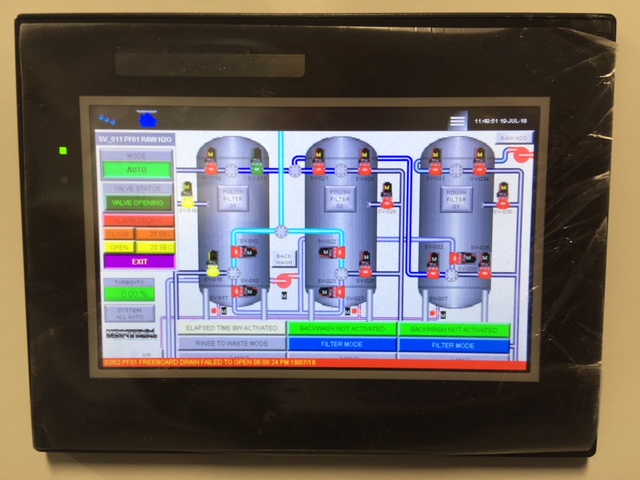

UFG designed and built a fully automated, turn-key, skid-mounted, water filtration system for the Red Dog Mine facility, which was assembled and tested in our facility in Nanaimo, BC prior to shipping to Delta Junction in Alaska. The water filtration skid was completely plumbed and wired to the Filter Control Panel (FCP) which was designed by UFG using an Allan Bradley PLC and touchscreen.

We incorporated our SS inverted Hub – Radial under-drain assemblies into this system which allows the vessels to be low-profile design for reduced overall height. We also utilized our UFG fabricated, side-outlet SS tee assemblies which support the valves and manifold piping from the filter vessels. This feature allows the butterfly valves and manifold piping to be mounted directly to the SS tees to be and completely self supporting.

When the system was delivered to Delta Junction in Alaska it was placed by Heritage Contracting into a specially built module. Heritage completed the piping and electrical connections along with various ancillary equipment such as turbidity monitors, analyzers, and controllers.

The water filtration system was transported via barge from Seattle, WA along with numerous other shipments to the western shore of Alaska and transported via transport on the final leg of this journey to the Red Dog Mine facility. Heritage Contracting then completed the site work required to connect the new module to the existing water treatment plant structure.

A UFG technician attended to the Red Dog Mine site in early 2019 to supervise the equipment start-up, media placement and commissioning of the FCP. The new filtration system was placed into service in early 2019 with only minor adjustments and immediately began to produce a high-quality, potable water supply to the facility.

The quality of water from the effluent of the new filtration skid surpassed the expectations of the entire team involved with this venture. The filtration media selected by UFG will remove particulate matter to below 3-mmicron at nominal loading rates.

The personnel at the Red Dog Mine facility are so enthused about the operation of this system, that it will likely result in another upgrade in the future to replace the old filtration equipment with a UFG filtration system having sufficient capacity to allow for replacement of the original filter system in this facility.