Hilcorp Alaska LLC (Milne Point Unit – Prudhoe bay, AK)

Hilcorp Alaska LLC (Milne Point Unit – Prudhoe bay, AK)

The Milne Point Unit (MPU) is located on the north slope of Alaska, adjacent to the Bering Sea. It is a privately

owned oil pumping facility of Hilcorp Alaska LLC (Formerly owned by British Petroleum Alaska) which has been in

operation for several decades. The facility which extracts and pumps petroleum through the Alaska Pipeline to the

lower USA, has several hundred employees and serves numerous contractors, sub-contractors and suppliers.

Having an adequate supply of potable water is a must for this facility to function without interruption. The facility

is primarily served via air, although some larger items can be delivered through an overland seasonal road

connecting the north slope with to other parts of the state.

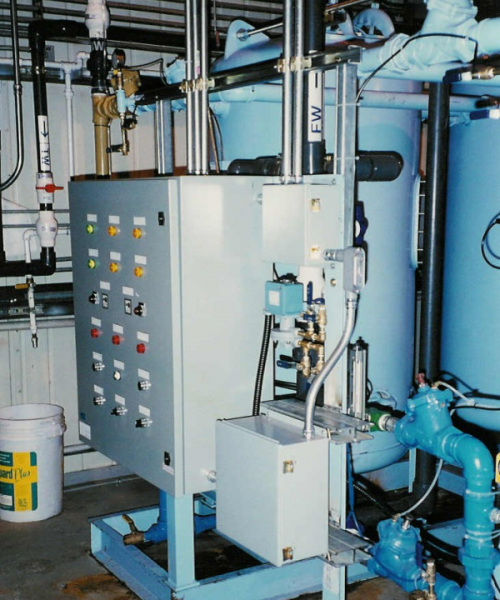

The old water filtration system was designed and built by UFG in 1997 when the facility at MPU went through an upgrade to improve water quality. The old water filtration system is still in operation, although it is nearing the end of normal life expectancy after being in continuous operation for 25 years. UFG has been providing support for other systems on the north slope and is well known to the Hilcorp team.

The operational / management team at MPU reached out to UFG several years ago with the desire to replace the existing unit with an up-to-date, fully automated water filtration system having improved performance and the ability serve that facility well into the future.

UFG referred the Hilcorp team to contact the operations manager at the Red Dog Mine site, which had recently installed a UFG direct filtration system. Hilcorp contacted the team at Red Dog Mine and were impressed with the feedback from the Red Dog Mine personnel. After several rounds of discussion and negotiations Hilcorp awarded UFG the contract to design, build and commission a new direct filtration skid for the MPU facility.

Upgrades

UFG designed and built a fully automated, turn-key, skid-mounted, water filtration system for the MPU facility, which was assembled and tested in our facility in Nanaimo, BC.Prior to shipping to Hilcorp in Alaska,the water filtration skid was completely plumbed and wired to the Filter Control Panel (FCP) which was designed by UFG using an Allan Bradley PLC and touchscreen.

One of the challenges facing the team was that the fact that the entrance to the building that houses the filtration equipment has extremely limited access. The filtration skid had to be designed in such a manner that every section was modular including the individual filter vessels, electrical connections, manifold piping and the Filter Control Panel. Compounding this situation was the fact that the height was also limited so everything had to able to be brought in through an existing doorway which could not be modified.

We incorporated our SS inverted Hub – Radial under-drain assemblies into this system which allows the vessels to be low-profile design for reduced overall height. We also utilized our UFG fabricated, side-outlet SS tee assemblies which support the valves and manifold piping from the filter vessels. This feature allows the butterfly valves and manifold piping to be mounted directly to the SS tees to be and completely self supporting.

The filtration skid was plumbed, wired and dry-tested at our facility to ensure that all components operated as designed. The individual skids were then disassembled at key locations and tagged for easy re-assembly at the site. The water filtration system was transported in a curtain type container, from our facility in Nanaimo, BC direct to the MPU facility on the north slope of Alaska.

When the system was delivered to Hilcorp in Alaska it was disassembled at key terminal points according to UFG instructions and moved into the facility without any glitches. The crew at Hilcorpcompleted the piping and electrical connections along with various ancillary equipment such as turbidity monitors, analyzers, and controllers.

Due to the current travel restrictions resulting from the COVID pandemic, UFG will assist the team at the MPU facility to commission the new system using a portable computer and Microsoft Teams.

We are confident that the quality of water from the effluent of the new filtration skid will surpass the expectations of the entire team involved with this venture. The filtration media selected by UFG will remove particulate matter to below 3-mmicron at nominal loading rates. The new filtration skid will provide high quality potable water to this facility for many years into the future.